ADA and ANSI A117.1 Accessibility Standards for Toilet Cubicles

When it comes to public restrooms, accessibility isn't just about being nice it's actually required by law. The Americans with Disabilities Act set some pretty specific rules back in 2010 regarding accessible toilet stalls. For wheelchair users, there needs to be at least 56 inches by 60 inches of open floor space inside these special compartments. Doors should swing outwards rather than in, leaving a gap of no less than 32 inches wide for easier entry and exit. Then there are those grab bars everyone sees but rarely thinks about. They need to hold up against 250 pounds of pressure and run along the back wall for around 42 inches. And let's not forget about the actual toilet seat height which sits between 17 and 19 inches from the ground. These measurements might seem arbitrary, but they make a real difference when someone relies on them daily.

Understanding ADA requirements for public toilet compartments

The ADA specifies a 60’ minimum turning circle in accessible stalls and prohibits protruding hardware that obstructs wheelchair maneuverability. Compartments for ambulatory users require entries between 35’ and 37’ wide, along with horizontal grab bars on both side walls to support safe transfers.

Common design violations and how to ensure compliance

Frequent errors include overlooked toe clearances (present in 87% of inspected facilities), incorrect partition mounting heights, and non-compliant latch mechanisms. To prevent these issues, use ADA-approved hardware kits and conduct pre-installation clearance checks using 3D modeling tools to verify spatial compliance before construction.

Fire Safety and Building Code Requirements for Toilet Cubicle Materials

NFPA 286: Fire Performance Testing for Interior Finishes in Toilet Stalls

Restroom partitions need to pass NFPA 286 testing requirements if they want to stay within legal boundaries. These tests look at how fast flames spread across materials, how much smoke they produce, and the rate at which heat gets released when things catch fire. Anything with a flame spread rating above 450 points or that generates too much smoke just doesn't cut it according to the latest ICC rules from 2023. Getting this kind of testing done typically sets back businesses around $28,500 for each location. And let's be honest, nobody wants to deal with the headache of daily fines that can top $5,000 if their installation fails inspection. Compliance isn't just about paperwork it's literally about keeping people safe from potential fire hazards.

IBC Regulations for Bathroom Partitions in Commercial Buildings

According to the International Building Code (IBC), buildings standing taller than 75 feet need their toilet cubicles to meet at least a 1 hour fire resistance standard. Now here's something interesting about code specifics: Section 603 actually allows certain flammable materials like HDPE provided they clear those ASTM E84 flame spread tests. Meanwhile, Section 714 gets stricter about sealing gaps between walls and structural supports. For places where safety is absolutely critical, think hospitals or major airports, many jurisdictions bump this requirement up to a full 2 hour rating through local modifications. Fire marshals tend to be particularly strict about these requirements in healthcare settings where patient safety concerns run high.

Flame-Retardant Treatments vs. Inherently Fire-Resistant Materials

Coatings that expand when heated can cut down how fast flames spread across plastic walls by nearly two thirds according to recent testing from UL (2023 data). The catch? These coatings tend to wear off after some time. Stainless steel panels and those reinforced with minerals stand out because they resist fire permanently without needing any special chemicals added during production. Sure, these options come at a price premium of around 35 to 50 percent initially. But most building inspectors seem to agree on something important: about 8 out of 10 professionals will go with materials that have official UL certification rather than relying on treated surfaces, as noted by the National Fire Safety Council last year.

Global and Regional Compliance for Public Toilet Stall Design

Meeting International Standards: ISO, CE, and CJJ 14-2021

Toilets in public spaces need to hit certain international standards if they're going to be safe and accessible for everyone who uses them. The ISO 9001 certification basically checks that materials are good quality and that manufacturing stays consistent across different batches. Then there's the CE mark which shows products meet European Union rules about health and environmental impact. Over in China, their 2021 code called CJJ 14-2021 actually requires each stall to be at least around 90 centimeters wide and specifies what kind of slip-resistant floor surfaces should be used. Most important standards worldwide tend to agree on things like how much weight walls can support before breaking (usually around 150 kilograms for stuff mounted against walls) and making sure materials won't corrode when exposed to constant moisture from people washing hands or cleaning.

Aligning Toilet Cubicle Materials with Local Building Codes

The choice of materials really depends on where things are installed. Coastal regions tend to go for stainless steel because it holds up better against all that salty air, whereas cities usually stick with powder coated steel since it can take a beating from vandals. When we're talking about areas prone to earthquakes, building codes get pretty specific about fire safety requirements. Most places want materials that won't catch fire easily, so they look for stuff rated Class A for flame spread. And don't forget about those certification papers either. Across the United States, local authorities generally demand smoke density tests that meet International Building Code standards, specifically looking for readings under 450 optical density when testing enclosed spaces like restrooms or storage areas.

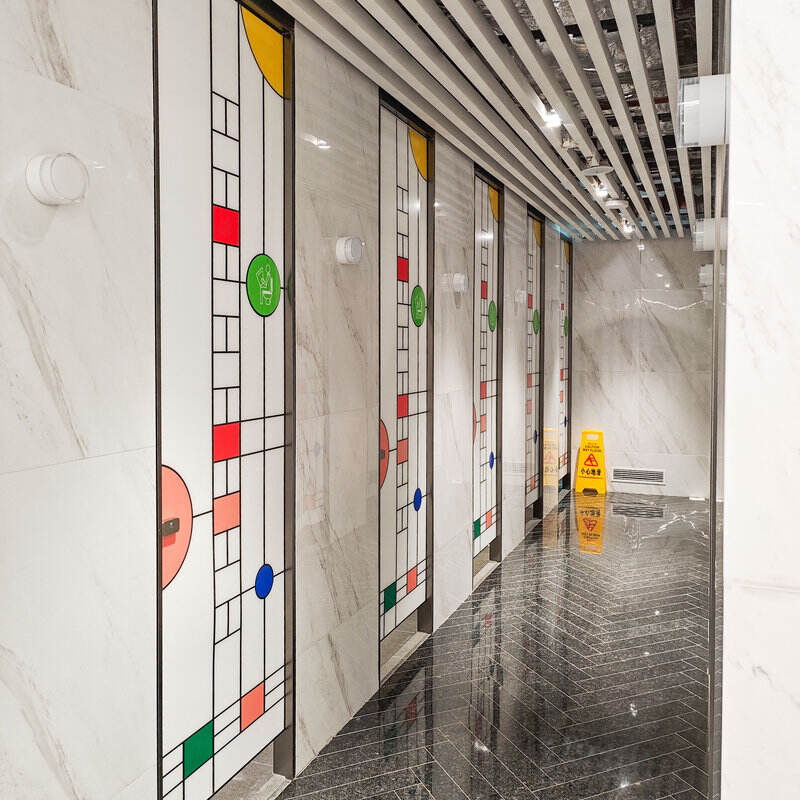

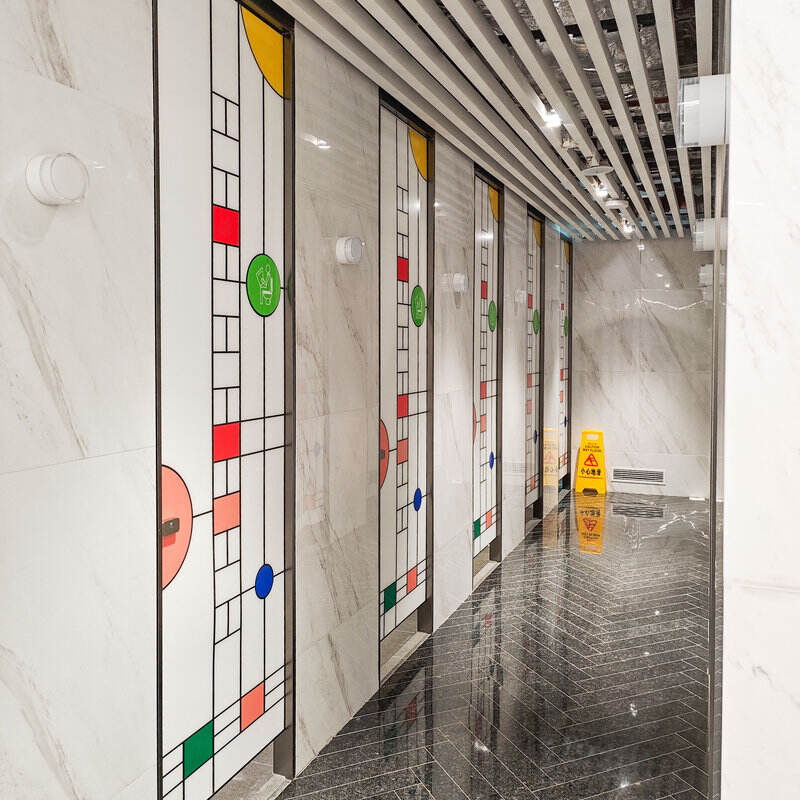

Durability, Vandal Resistance, and User Safety in Toilet Cubicle Construction

When it comes to public toilet cubicles, the materials used really matter because these spaces get hammered day in and day out. Most modern safety standards point toward impact resistant options like stainless steel and those tough phenolic resin boards, especially where crowds gather regularly such as at busy airports or packed stadiums during big events. What makes these choices stand out is their ability to handle everything from daily wear and tear to the occasional vandalism attempt. They just don't scratch or dent easily and handle moisture much better than older materials did. Maintenance crews report seeing maintenance costs drop somewhere around half when switching to these durable options instead of traditional materials, though exact savings can vary depending on location and usage patterns.

Impact-resistant and vandal-proof materials for high-traffic areas

Stainless steel partitions with reinforced anchoring systems deter forced entry. HDPE cubicles feature graffiti-resistant surfaces that maintain structural integrity after more than 200,000 cleanings. Leading designs incorporate tamper-proof fasteners and 18-gauge steel supports to counteract common vandalism tactics such as door slamming and hinge tampering.

Critical safety features: anti-ligature fittings and smooth edge designs

Toilet stalls in mental health centers and educational institutions need rounded edges at least 2 millimeters thick plus hidden hardware so people can't attach anything dangerous. The doors should have closers that take around ten seconds to shut fully, along with magnets instead of regular latches which helps prevent fingers from getting caught when someone tries to close them too fast. There are also emergency release systems built into these doors so they open outward easily even if someone is struggling against them. These doors only need about five pounds of pressure to work properly, which actually solves most problems related to accessibility issues reported across different facilities.

Balancing aesthetics with long-term safety and durability

Textured laminates now replicate natural wood finishes while maintaining over 3 hours of fire resistance. Color-through phenolic surfaces hide wear and meet NSF/ANSI 2 hygiene standards. Three-stage powder coating processes create seamless, chemical-resistant finishes that remain intact after 15+ years of commercial cleaning.